Lektion 1,

Topic 1

In Arbeit

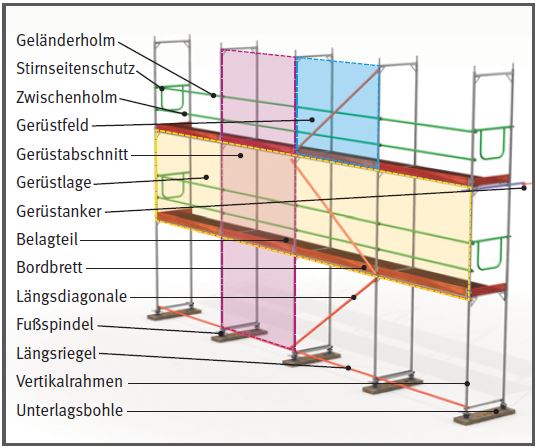

Facade scaffolding

Hazards

- Incompletely erected scaffolding and unauthorized modifications to the scaffolding can lead to fall accidents or scaffolding toppling.

General information

- Façade scaffolding is scaffolding with length-oriented scaffolding layers that stand directly on the ground.

- Façade scaffolding must be stable, accessible via a safe access route and safe to operate (no risk of falling).

- Proof of usability as a generally recognized standard design is provided if, for example, a general building authority approval (issued by DIBt) and the associated instructions for assembly and use (AuV) are available.

- Facade scaffolding can be created, for example, by:

- Scaffolding systems (e.g. frame and modular scaffolding) made of prefabricated components (standard design - general building authority approval and AuV),

- Tubular steel coupling frames (standard design - DIN 4420-3 and AuV).

- Depending on the work to be carried out, select the load class and width class and determine the stud and transom spacing and decking thickness.

- At least load class 4 is required for setting down loads with the hoist.

| Load classes of working scaffolding | |

| Load class | Uniform distributed load kN/m2 |

| 1 | 0,75 |

| 2 | 1,50 |

| 3 | 2,00 |

| 4 | 3,00 |

| 5 | 4,50 |

| 6 | 6,00 |

| Width class/width w of the scaffolding layer in m | |

| W 06 | 0,6 < w < 0,9 |

| W 09 | 0,9 < w < 1,2 |

| W 1,2 | 1,2 < w < 1,5 |

| W 1,5 | 1,5 < w < 1,8 |

| W 1,8 | 1,8 < w < 2,1 |

| W 2,1 | 2,1 < w < 2,4 |

| W 2,4 | 2,4 < w |

Protective measures

Underground

- Use a load-bearing surface as a support surface for the scaffolding.

- The load-bearing capacity of the subsoil may be impaired by e.g: Shafts, sewers, cisterns, insufficiently compacted subsoil, proximity to embankments of construction pits and trenches.

- Use load-distributing underlays to improve the load-bearing capacity.

- Do not use building materials such as bricks as a base.

- In the case of sloping surfaces, create a load-distributing base so that the scaffold base can be placed horizontally.

- Only use scaffolding with a base spindle as a support; do not place tubes or frames directly on the ground.

Anchoring

- Anchor the scaffolding continuously with the assembly to load-bearing components of the façade in a tension- and pressure-resistant manner. The first scaffolding bay must be secured against tipping over as soon as it is erected (see AuV).

- Arrange the anchors close to the scaffolding nodes.

- If no suitable anchoring base is available or if the anchoring grid specified by the AuV cannot be adhered to, measures to ensure stability must be specified in the installation instructions.

- If ballasting is necessary, only use solid material (e.g. concrete or steel weights); do not use liquid or granular materials in containers.

Additions ![]()

- All workstations must be accessible via safe access points. Suitable access points are elevators, transport platforms, stairs or ladders. At least one access point every 50 m of scaffolding length (unwinding).

- Access via internal ladders is permitted

- Up to an ascent height of 5 m

or - for work on single-family homes,

if the existing hazards (e.g. extensive material transport, closing of access openings) are taken into account in the risk assessment. - Up to an ascent height of 5 m

- If elevators, transport platforms or stairs cannot be used due to structural conditions, system-bound indoor ladders can be used.

Scaffolding covering

- In the standard version, each scaffolding level must be fully designed.

- When scaffolding around a corner of a building, run the full width of the scaffolding planking around the corner.

- For system-free coverings, provide sufficiently large overlaps in the area of the transoms.

- The covering must not rock, lift or move (covering safety device).

- On the inside of the scaffolding, the horizontal distance between the decking and the structure must not exceed 0.30 m.

- Keep flaps in access decks closed after climbing through.

Side protection

- Side protection consists of a guardrail rail, intermediate rail and toe board and must be fitted to the outer and end faces of the scaffolding.

- Fit side protection on the inside of the scaffolding if the horizontal distance between the decking and the structure is more than 0.30 m. The toe board may be dispensed with on the inside if work is being carried out on the façade.

- Secure internal ladder aisles that are only used vertically as traffic routes with at least two-piece side protection, including the end faces.

Labeling

- Labeling (sensibly at the access

) is part of the examination and a prerequisite for the inspection, contents:

) is part of the examination and a prerequisite for the inspection, contents:

- Name, address and telephone number of the scaffolding manufacturer

- Type of scaffolding

- Load and width class

- Information on any restrictions on use

- Warnings

- Date of the last audit

- Mark scaffolding/areas that are not ready for use with "No access" signs and cordon off access to the danger zone.

Exams

- Scaffolding manufacturer: Inspection by a "person qualified to inspect" after completion and before handover to the user to determine the proper condition (verification test report).

- Scaffolding user: Inspection by a "qualified person" of the respective user before use to determine safe function and freedom from defects (verification checklist).